Rapid Fire

Rapid Fire

The Evolution of PPE Since 9/11

Learn about the changing culture within the fire service that has led to a better understanding of health and safety needs for firefighters through advancements in PPE in the years since 9/11.

WHAT YOU CAN EXPECT TO LEARN:

- Conceptualization of today's particulate blocking hoods

- Expectations of gear inspections and cleaning

- Inefficiencies in past PPE technology

- Ergonomic design of modern turnout gear

- Introduction of alternative PPE

ABOUT OUR GUEST :

Jim Reidy was a Lieutenant on Ladder 46 for the San Antonio Texas Fire Department (SAFD) where he was a firefighter for 33 years. He was also an Assistant Safety Officer and was the SAFD Quartermaster in 2018. He was involved in PPE for 30 of his 33 years and served as Co- Chairman of the SAFD/Local 624 Firefighting PPE Committee, as a member of the SAFD Occupational Cancer Committee, Tool and Equipment Committee, and Apparatus Committee.

Jim is a member of the NFPA 1971-1851 Committee representing the Texas State Association of Fire Fighters. He currently serves as Helmet Task Group Chair for the next edition of NFPA 1971. He serves on the Texas Commission on Fire Protection Firefighter Advisory Committee as a member and past Chairman and is a Firefighter Cancer Support Network Rep in South Texas.

He also speaks at a variety of venues and events on Firefighter PPE Risk Assessment, Use, and Selection along with Firefighter Cancer Prevention and is known as a vocal advocate for firefighter health and safety.

ABOUT THE HOST:

Battalion Chief Keys completed a total of 31 years of service, beginning as a firefighter for a high volume station in the Bronx. As a Captain and Lieutenant, he served various municipalities including Midtown Manhattan, until settling into East New York Brooklyn, where he became Battalion Chief. Within his new role he took charge of Research and Development where he learned how new innovations are tested and introduced to the fire service.

Learn more about Fire-Dex products and services by visiting, www.firedex.com

Join the Conversation by Following Us at:

Facebook: https://www.facebook.com/FireDex

Twitter: https://twitter.com/firedex

Instagram: https://www.instagram.com/firedexgear/

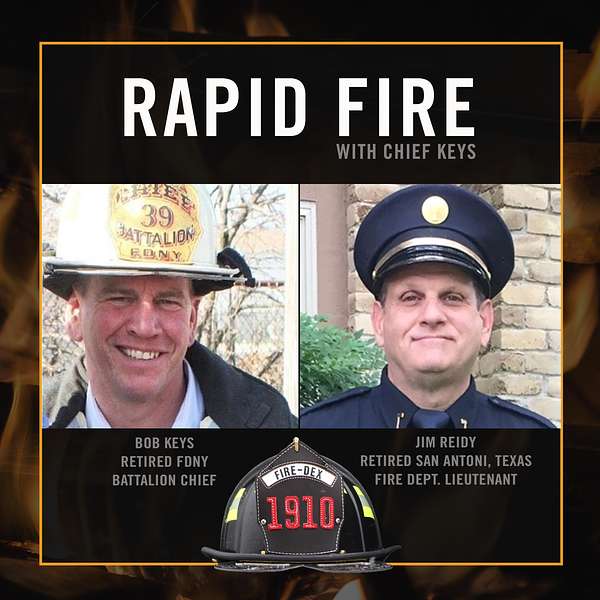

Bob Keys, Retired FDNY Battalion Chief: [00:00:00] Hello, and welcome to Rapid Fire, a podcast hosted by Fire -Dex, dedicated to sharing best practices and lessons learned in hopes of making firefighting a little bit safer. I'm your host, Bob Keys, Retired Battalion Chief from FDNY and today we're fortunate to be joined by my good friend and recently retired Lieutenant Jim Reidy of the San Antonio Fire Department.

How are you doing today?

Jim Reidy, Retired SAFD Lieutenant: [00:00:27] Idt's a beautiful day here in south Texas.

Bob Keys, Retired FDNY Battalion Chief: [00:00:29] So recently retired. I, uh, I think we could count that in the number of days. How long have you been retired?

Jim Reidy, Retired SAFD Lieutenant: [00:00:36] Well, it's been 34 days, but who's counting.

Bob Keys, Retired FDNY Battalion Chief: [00:00:39] And how many years did you serve in San Antonio fire department?

Jim Reidy, Retired SAFD Lieutenant: [00:00:43] 33 years and four months.

Bob Keys, Retired FDNY Battalion Chief: [00:00:45] Awesome. Thank you for your time. Thank you for dedication. Thank you for serving your community the way you did, and really thank you for serving the entire firefighting community. We'll get into that in a few minutes.

The highlight of this podcast is going to be never forget. And today we're going to discuss and remember the events of 20 years ago this month, we're following our bowels taken in the aftermath of 9/11 to never forget. It's not just a bumper sticker. It's not a jargon. It's not a slogan. It's a lifestyle. It's a vow to never forget.

We remember the supreme sacrifice that was made by the 343 courageous dedicated FDNY firefighters. We also remember the brave NYPD and port authority PD, police officers who gave their lives, helping others escape the collapsing world trade center buildings.

We'll also never forget those who continue to suffer and die each year from 9/11 related cancers and illnesses, including my colleague firefighter, Ronnie Schwartz from Ladder 107 in Brooklyn, who died this year from his exposure to the toxic dust at ground zero. Before we go further into the podcast, I'd like to ask Jim about his experience on 9/11 and then days and months afterwards.

Jim Reidy, Retired SAFD Lieutenant: [00:01:53] As I was recalling it, I was home that morning and like every morning I get up and watch the news and the news camera on. And, and that was back when we, uh, we actually relieved at 12 o'clock. So I wasn't due to go until 11. And I saw it that morning. I watched a little bit of hair at the house and then. I rushed into the fire station like everybody else did. And we watched more of it on the TV and as it was going along. And just looked at each other with the bewilderment, wondering what the heck was going on. I mean, it was a focal point I imagine in every firehouse across the country that day, and you don't really absorb what's going on until later on.

But. Still went about our business that day, did what we had to do, answered every call. We all wondered what we could do, what we wanted to do and what was going to be the right thing to do. And so like everybody else, we just did our jobs that day. And really as a, as a tribute to the guys that passed away that day, went about and did our jobs and serve the citizens in the best way.

Bob Keys, Retired FDNY Battalion Chief: [00:03:05] I too was off that morning and I got a call from a neighbor about a plane hitting the world trade center and flipped on the TV and saw the second plane crash. And, uh, just before the first tower collapsed, I got a phone call from work total recall every FDNY firefighter was to report back into work.

Um, Hopped in the car and, and fought traffic because they, all the highways were closed down. The big traffic signs above said New York City closed, turned around here. So the traffic jams were intense and, uh, struggled, but made it into work just after both towers had collapsed. And that, that day continued to be a crazy, crazy day for, for me, worst day of my life.

But, uh, I'd like to move on and as part of our vow to never forget and dedication. Making fire-fighting a little safer, as we say that this podcast is all about, bring up an interesting fact.

A contributing factor to the continued loss of life of first responders on 9/11 was a lack of sufficient personal protective equipment or what we call PPE.

FDNY had not had a total recall of all its members in almost 30 years. And that was for the blackouts in the seventies, certainly in need of first responders, but not as big a need for PPE and breathing protection. FDNY could not. provide breathing protection for the thousands of firefighters who responded to help rescue the victims that were trapped and injured down in world trade center.

So moving forward a lot has evolved in firefighting since 9/11. We now have a better understanding of the influence of cancer on firefighters, the influence of heat exhaustion, the better health and safety requirements and keeping firefighters fit to be able to do their job. And so. These instances have created innovations that improve everything to help firefighters survive and enjoy a healthy retirement.

And those include building regulations that have changed NFPA standards that have changed, and as we're talking about now, the evolution of personal protective equipment that manufacturers are providing to firefighters to help them conquer a fire and walk away healthy at the end of their career.

Cancer in the fire service since 9/11 is it at astonishingly high levels. It has caused the firefighter community to change our culture and look at ways to better protect those who serve. We have learned that there are many ways, of carcinogens enter into a firefighter's body other than just by inhaling smoke. So over the past 20 years, since 9/11, PPE has evolved in many ways for the better. Our gears design now to better block carcinogen.

And also reduce heat stress. And we know that heat exhaustion is the silent killer of firefighters, even at higher rates than any other. Cause. So today, Jim and I are going to talk about those changes and how they've come up. Jim is our subject matter expert or know it all here on this call today. And we'll share his life's work at protecting firefighters by changing standards.

He has served as the PPE committee chairman for the San Antonio Fire Department. Those that don't know San Antonio is the seventh largest city in the United States. They have, 1100 sworn firefighters. And he's also served on the technical committee for in 1971, the National Fire Protection Association standard for how bunker gear has to be manufactured, to be certified and also serves on the technical committee for NFPA 1851, which is the selection care and maintenance of bunker gear.

Jim also serves on the Texas commission on Fire Protection, which I'd like him to explain, because it is very unique, the way Texas treats NFPA standards compared to other states in the U S and Canada. Can you expand on the Texas fire commission, Jim?

Jim Reidy, Retired SAFD Lieutenant: [00:06:53] Sure. The Texas commission on fire protection is basically a regulatory agency that regulates all the paid firefighters in the state of Texas and volunteer firefighters that voluntarily want to be regulated, but it's extensively for the health and safety of the firefighters that it sets up equipment standards, some operational standards and curriculum standards for certifications.

If you get paid, in any sense of the word or you belong to a paid fire department, you're regulated. And I think we have about, I want to say 23,000 people that we regulate right now. And it also includes colleges that have fire programs or training facilities. And we also regulate the online training facilities that operate in the state of Texas.

It's a 13 member commission that has, um, four public members, uh,2 chiefs representatives 2 firefighter, labor representatives, volunteer representative, arson, college, uh, that's off the top of my head. That's what I remember. And then it has different committees that assist the commissioners with technical expertise.

I sit on the firefighter advisory committee for the fire commission and basically it's the technical committee for the fire commission. I was the chairman for, I guess about 15 years, and now I'm a member of the committee we adopt. Into law and into the constitution.

We adopt standards and so the NFPA standards are adopted as statute 19 71, 18 51, 19 81 is the breathing standard, 1852 as a selection care and maintenance breathing apparatuses. PASS, two two out, the live fire training, things that readily impact the firefighters and their safety are adopted into law.

So say for an example of 1971, anything that the firefighters paid firefighters regulated firefighters use has to be compliant with 1971 and also has to follow 1851. So we have to follow all the cleaning standards, all the, uh, care and maintenance staff. It is the line firefighters best protection to ensure their safety and health and that their equipment is proper, safe and okay.

Bob Keys, Retired FDNY Battalion Chief: [00:09:13] And if by chance I municipalities is all well, we can't afford to buy our firefighters, uh, new gear when it expires, uh, the commission will, excuse the pun, hold their toes to the fire and make it a financially punitive if they don't follow the standards. Is that correct?

Jim Reidy, Retired SAFD Lieutenant: [00:09:28] There are those financial penalties in the statute? Yes. The biggest one I can remember is a certain metropolitan department in north Texas never inspected their SCBAs and didn't keep records of it. And so the commission applied a find for each SCBA that was not inspected. And then up-to-date then they were nice enough to credit them when they had the buy, all those new SCBAs.

It's an encouragement to comply. And to be honest with that, most departments in Texas are very compliant. And the ones that aren't sometimes are just a little behind the curve on information. So, and the commission does a really good job at trying to get the information out, but, you know, in our, our profession, sometimes the important financial information kind of trickles out slowly of, of what you need to do.

But, um, it goes pretty well. And we have a certification for our fire chiefs in Texas. And part of that is to come down and attend meetings and learn about the statutes that they have to follow. So that helps a lot of the out of state fire chiefs that come in and aren't used to that type of regulation

In fairness, we're a pretty compliant state. Nobody's ever a 100% but we're pretty compliant. Our new Executive Director, Mike Wisco does a fantastic job at communicating with the fire chiefs around around the state.

Bob Keys, Retired FDNY Battalion Chief: [00:10:48] Thanks, Jim. Yeah, Mike Wisco, a ex-fire chief from Galveston, Texas has a great stories to tell about dealing with tragedies and hurricanes in that community. He's a firefighters advocate for sure.

And I think that I would sum up saying that the Texas commission is really the firefighters best friend. They exist to better protect firefighters. I would love to see more states adopt a commission on fire protection like Texas did. I, I think it would say firefighters lives by making municipalities more accountable for what's expected of them and maintaining protective equipment for firefighters.

Jim Reidy, Retired SAFD Lieutenant: [00:11:25] And you know, the easy thing for a fire chief is if something is mandated, in law. There is no politics involved. It's just, you have to do it. So it's an easy budgetary item. I'm mandated to do this, so we have to budget for it. And that's what we always tell them. We're actually helping you out.

Bob Keys, Retired FDNY Battalion Chief: [00:11:43] Well, thanks for it. So the time and effort that you've put into to that committee and sharing that with everybody's listening.

So let's, um, let's dig into some of the changes that we've seen you and I both in the past 20 years, since 9/11 to PPE, I think the one that jumps out to me the most and is probably in my second to going from three quarter length canvas coats and a pull up boots.

We went to two-piece coats and pants, uh, the current bunk of gear designed back in 1995. And FDNY, but since 9/11, the biggest change or the biggest improvement and innovation. I see and and more and more firefighters are telling me what a difference it's making on them as in particulate blocking hoods and you were instrumental in coming up with test data and visual testing data that showed definitively that firefighters absorbed carcinogens through their face and neck. And you did so by a test that many of our listeners might have seen the pictures of the firefighter lit up in fluorescent yellow. Can you explain how you were involved and how the IAFF was involved in the research triangle institute's fluorescent aerosol screening test that showed how these carcinogens attached to the skin of firefighters?

Jim Reidy, Retired SAFD Lieutenant: [00:12:58] I had a friend, actually my driver, he got brain cancer. And, uh, it really struck me at the time. And I had the opportunity to sit in and see a presentation by Dr. Stuart Baxter about the contamination and the carcinogen contamination. And I wondered how that brain cancer was becoming so prevalent in our firefighters and thought that the only unprotected place that we have.

Was that area from the shoulder step, top, everything else had a barrier in it, putting the helmet, I guess you would say, but everything else had a barrier except our hoods. And I wondered what was happening there was that a possible place of absorption and so I, I did a little research and talk to some people and some doctors and started to find out that that was an incredibly absorbent area.

Dr. Baxter did a nuclear bonding test of how the skin absorbed in those areas and it was significant. And so we didn't have a barrier there. That area was truly very significant in its absorption. So basically I wondered out loud to people and said, we need to find something to put in the middle.

Putting the middle, some kind of barrier product to block those carcinogens and contamination from the smoke that was getting on our necks and, and absorbing into our bodies. We talked about that a little bit and, uh, I did a little research and Jeff Stall helped me a little bit, but eventually I found a picture of the FAST test and it's the Fluorescent Aerosol Screening Test or the original picture that you might've seen is a hazmat warfighter test that they did a Research Triangle Institute (RTI). Research Triangle is a testing facility in the Carolinas, in that area where all those really smart scientists all live and went to school in the Carolinas.

But RTI is what it's called, but it was a war fighter. A hazmat test that showed that originally, I thought, well, why not? Why can't we do the same thing and have it tested. And money came in through the factor. Money was the deal, but we actually did some research on it and it's an area that we needed to address.

Lo and behold, the IAFF recognized that that was an issue and it was a place that we had an issue. So they paid for the test at RTI and it was a significant amount of money. One time test, significant amount of money. We actually, San Antonio, we supplied the bunker gear because one, we knew it had been taken care of cause we wash our gear here. So the bunker gear had been taken care of. It was in good shape. It wasn't brand new and it wasn't 10 years old. So we sent that out and they conducted the test.

And lo and behold, the pictures that you saw eventually down the line, they say a picture's worth a thousand words and I think that picture was probably worth a million words of what it showed us of the permeation through that every spot, except the spot that didn't have a barrier that led us to, we're going to do this and we're going to develop some kind of product.

And so, I was put in charge of the hood task group, which our main focus was really trying to figure out, develop a hood or to set up the standards, to develop a hood and let industry come along and do some innovation.

We set up the task group and my good friend, pat woods, who was an FDNY research and development captain, but he was like the main cargo over there. He was my best friend and assistant in that project and helped us immensely. He should have a lot of the credit for what we ended up coming up with. So really the task groups job was to not help anybody develop a product, but facilitate the innovation, set up some testing that would protect firefighters from having basically a plastic bag put in between those two layers, but block the particulates, but it still needed to breathe a little bit.

And so we went through that process and with a great deal of help from underwriter laboratories, I'm in a new school. We developed some very basic minimum standards for those barrier hoods the recognition of that picture from the RTI test and what it meant for the contamination in that very, very absorbent area really helped drive that whole project.

And what we came up with in the beginning was first-generation. I would imagine we're probably at fourth generation and one of the issues I was really afraid of and so were the firefighters in the group was having something that was too overdone, too protective. The TPP was too high. And now in this fourth generation, it seems like we're coming back around to a little thinner, more comfortable, more breathable, but also a lower TPP to give you the ability to have recognition of the fire outside of you. That was one of the biggest concerns that everyone had was we need to make sure that the firefighters still have recognition of their surroundings outside of them; the unofficial heat thermometer.

Basically, I still tell firefighters if you feel that fire. Through the hood it's time to really, you know, should get your attention and if you feel it through your gear, there's really only one decision to make.

And I'm very proud of what we did. FDNY was instrumental in setting up and helping us with the, uh, the measuring device to make sure that the opening was wide enough, Pat and Eric and George really helped us out quite a bit. But I I'm very proud of that project. And I think we really did something good for the firefighters and like you, and I've talked about in the past, basically what you want to do is leave it a little better than you found it. And I really feel like with a lot of help, I've been able to we'll do that. So..

Bob Keys, Retired FDNY Battalion Chief: [00:18:55] Thank you, Jim, for your dedication to seeing a need for change, seeing a need for innovation and driving the process, which is extremely difficult to get a new product that didn't even exist at the time to become a standard, uh, required, uh, protective standard for firefighters. You know, I look upon you and that group of guys, who I had the pleasure of working with at FDNY R & D Eric and George Grammis and pat woods truly dedicated individuals, um, who did leave the fire service better than they found it.

I would say, as a testimony to your effort, you as a committee and the whole NSPA. If you talk to a fire instructor from any academy across the United States who is now wearing a particular blocking hood, as they burn three, four or five times a day, they will tell you to a person that they noticed the difference when they go home.

We all know that. Do you, as you guys in Texas say, make a fire or a we in FDNY, say, catch a job. You come back to the fire station, you take a shower, go home at the end of their shift. And my wife would say, you stink, go take a shower, said I did take a shower. But those carcinogens that had entered my body are continuing to out gas.

And I still smell like smoke because it's inside of me working its way out fired instructors and academies today have come to me and. Now that I'm wearing a particular blocking hood. When I go home after four burns, my wife says, how come you didn't burn today? Didn't you guys do any live fire training?

Well, yeah, we did, but I'm wearing a different hood now. And so I don't stink like smoke. So to me, that's a testimony right there. When you can go home and your loved ones, don't have to smell the carcinogens coming out of your body. You guys have done a great job of changing. The fire service for the better.

And thank you on behalf of, uh, every firefighter that is now wearing a particular blocking hood. One other thing that came out of that. So rest and aerosol screening tests at RTI showed that there was particles that was suspended in that chamber that as the firefighter did all simulated activities, his gear compressed and relaxed and compressing, so created like a bellowing or a breathing in and out.

Um, some of those particles made their way onto the ankle area and the cabs of that firefighter around his wrists. There was a transitional area there that was not totally protected and a little bit also on his belly area. The pictures showed some penetration in that area. So we've seen a bunker gear manufacturers in the last six, seven years develop kind of smoke barriers, elastic skirts, sleeves and ankles to block out some of those carcinogens from entering inside the bunker gear ensemble.

Can you speak to any of that gem about how those kinds of standards were put into the 1971 document?

Jim Reidy, Retired SAFD Lieutenant: [00:21:49] I think earlier on we, we all noticed that, the people that actually do the firefighting, noticed that we would get that water down that, especially that wristlet area.

I believe that there was already ideas and designs that tried to block some of that water from coming into that area. And then the natural evolution was maybe to tighten that up a little bit, but I do know there was already products for the arms and the legs are difficult area because depending on what kind of boots you wear and how wide open the barrel is on the top, it depends how much bellow you get up the bottom.

I've talked to firefighters that have told me why I felt the heat all the way up my leg. And then I talked to same guys they're guys in the same department that looked at me like what? Oh, I think sometimes it's just size and situational, but I mean, it is a, it is a reality, I think in the the RTI test, one of the things you have to know is that the person that actually put the gear on and was not a firefighter. He was a an employee, but I didn't see the whole put in a non taking it off thing, but, uh, there might've been a little, uh, transfer in one spot, but the opening spots where they openings all are, I think there's know there's there is some transfer in there.

One of the problems is before, as you couldn't tell what concentration. So if it laid on the top, That just showed the fluorescence. Now my understanding is they have the ability to tell how much concentration it might be very concentrated in certain areas. And in some areas it might be a little transfer or maybe just a light dusting on the top.

So the wristlet arm one, pretty much been in play for a little while and they proved it significantly. The leg one is difficult because if you close that leg in, or you put a barrier on the bottom of that leg, then there's a better chance that it'll get caught up high and you might get burned and you might get because the leg will get caught up on the top of your boot or even over the top of your boot. You know, that when you crawl down a hallway, if that leg is originally too short, sometimes it'll get caught up over your boot. So, I mean, that's a tricky proposition from my perspective, what you're really looking at is, is operationally does it work?

And you just have to make sure that you get everything cleaned afterwards.

Bob Keys, Retired FDNY Battalion Chief: [00:24:11] Yeah. I think that those designs are still a work in progress. I think we'll see some better products come down the line that like riding up as a complaint, many firefighters I've talked to that are, are trying to get that to work, but it does cause those pants to rise up and leave you unprotected.

Jim Reidy, Retired SAFD Lieutenant: [00:24:24] After 9/11, when there was a big push to close everything in all the way around and it was admirable, but some of the manufacturers were trying to answer those questions, but designs were not functional for what we actually do on a daily basis.

Bob Keys, Retired FDNY Battalion Chief: [00:24:42] So speaking of functional, that's a great segue, Jim.

One of the other biggest changes I've seen in the design of bunker gear since 9/11, is that manufacturers are making much more ergonomic coat and pant designs. First-generation of bunker gear was kind of like a, a bulky overcoat and a one size fits all pair of pants that did not allow us the kind of mobility we wanted climbing ladders, working in confined space areas inside a vehicle crash, trying to extricate a victim.

It was just not a form fitting. And I've seen much better designs now by manufacturers to, to address that issue for firefighters to reduce the coat rise when they're lifting their arms over their head, by changing the seams, better, protecting the crotch area with, by not putting seams in it, which is a costly repair that happens to the moisture barrier.

There are lots of innovations in design that I've seen in the past 20 years wouldn't you agree to that?

Jim Reidy, Retired SAFD Lieutenant: [00:25:41] Well, yeah, as an industry, we've definitely evolved that's for sure. I know that I've had the opportunity to meet some of the design people. Then they're coming from garment industries and industries, parallel industries, but not actually firefighting and bringing some of their design ideas into the, into the process, but we are in a unique profession for what we do in an all hazards environment. It's difficult to get that design just right for everything. That's a challenge. I'm sure of that.

But yes, the designs are, they are much better than they used to be much more of a ergonomic .We're not wearing a suit to go to a dinner. We're wearing a firefighting outfit. It has to be a little different. It doesn't wear like 99% of the rest of the clothes in the environment.

Bob Keys, Retired FDNY Battalion Chief: [00:26:26] So great point there, Jim.

Often garments, coats and pants are designed for somebody who's standing at attention, the seems to fall straight, and we all know that firefighters. Fight fires standing up straight at attention. We're crawling down a hot hallway, climbing a ladder we're on our hands and knees doing a primary search. So designing gear that has partially flexed elbows and knees has led to less resistance in trying to do your job. Uh, if your if your elbows are forward, like they are doing almost all firefighting work, why should you have to bend that fabric? Why not start with it that way? At least partially.

And the same thing with your knees, we don't stand up straight fighting fires. And so why not have the knees start out partially bent. It's reduced the stress and it's improved the overall comfort level to the gear.

So in addition to just design Jim, we've seen a lighter and more flexible fabrics in both in the outer shell and in the thermal liner, the inner liner being much more comfortable getting in that when it's wet, can you speak to what you've seen in the last 20 years and fabrics that have made firefighting more comfortable and better protective at the same time.

Jim Reidy, Retired SAFD Lieutenant: [00:27:42] You would probably laugh. I'm going to go backwards a little. When I first came on the job, you got one low bid set of gear. And then after that, you had to buy your own in Texas. They changed the law in oh one. It was before 9/11. They changed the law then, or the year before.

So then it was the fire department, had the purchase provide and maintain every set of gear. So after the city started buying me my gear, I've only been in two types of gear and the original gear, the face cloth and the shell. And the difference from then to now is really significant. And it, it has thinned up a bit and that's contingent on what kind of materials you use and how you specify your gear.

But I think the real advantage is, is that we've come down a little bit. It's a little thinner but it's still very functional for what we do, but then you have to also factor in that, the fires then, and the fires now; they're a little different because now they advanced to flash over so much faster. So the heat builds up so much faster. So you really have to have that outside shell really has to be, it has to protect you. And you're more likely to get direct flame impingement now than you ever were in the old days before the, the materials in society started to change. I mean, I think we've really evolved in the face cloth now on the inside, the thermal barriers are just light years better than they used to be.

And you have a choice, you know, you have a choice between the hydrophylic that absorbs the, or likes the water that comes off of your body and hydrophobic that just beats it up. Yeah. Theoretically it evaporates, but a lot of times it just rolls down into your boots or your clothes or whatever.

I think the gear is better. It's more protective in good ways. It's better built for the fires of today with the materials that burned today, because we all know that the materials today are different than the materials of 20, 25 years ago. And so you have to build that gear to protect you really from those fires today, but also the carcinogens.

Bob Keys, Retired FDNY Battalion Chief: [00:29:48] Right. Exactly. Thanks for sharing that.

So one of the other innovations, I was lucky enough to be involved in when I was in R & D at FDNY is new reflective trim technology that has evolved in the past 20 years since9/11 original trim that we were wearing back in those days did not have great reflective properties. When it got wet and worn out a little bit, it started to lose its ability to reflect the reflective beads could be rubbed off.

So we did a wear trial, three season, wear trial at FDNY throw across all five boroughs and found out that there was a type of reflective trim that did not lose its ability when it was worn and wet. And, uh, we're able to switch to that material and have seen good results in that reflective ability on those wet dark nights on highway crashes that still continue to be tragically killing police officers and firefighters every year due to drivers not being able to see the firefighters operating on those highways in the middle of the night.

We've also seen an evolution in, uh, trim that no longer requires extra thermal material behind it. And maybe Jim, you could speak to this about the NFPA standard that talks about stored energy studies have shown that some reflective trim holds on to the heat more than others. And so they require manufacturers to put extra thermal material behind certain types of reflective trim industry has come out trim that does not store heat as much as previous designs. And so we're able to reduce the amount of additional thermal material packed into our coats specifically.

Can you, uh, speak to that for us?

Jim Reidy, Retired SAFD Lieutenant: [00:31:33] I don't know if you know this, but when you guys were testing, Reflect the material we were doing it at the same time.

We were doing that at the same time and had the same excellent results. I will tell you that laughingly, the comment that I would get was that it was too bright. It would reflect the material was too reflective, but I kind of laughed at that people that are just born to complain. One of my favorite sayings is, uh, on a hot August day somebody will complain that the beer is too cold.

For years and years and years, that stored thermal energy we would, and you know this too, I mean, you would get burns in places that straight up on underneath the reflective material and the where, where the reflective material was on your body. If you got into a really high heat situation that was dangerous, you would get burns underneath them.

Areas where that reflecting material was. And it would just, it would soak in there and sink all the way through. I know, you know, Barry Burkowski and I've seen the world of burns that he got from his reflective material when he got caught in that flashover. I'll never forget that that's etched in my mind, forever. But that in and of itself and more burns afterwards, start people thinking about that stored energy and how it's starting to sink through.

And so we worked on that on the committee level for quite a while, because it was kind of a adding material in underneath those areas was a kind of a controversial deal at the time because we were trying to lighten them gear up and make it a little more breathable. So in and of itself, you're adding material and that just makes it less breathable. But underneath those reflective areas, the breathability pretty much goes out the window. Anyway.

So, and we came up with that, adding some material and because some of the manufacturers also were adding an extra layer or. Partial layers of material in high compression areas to give you a little buffer and a little air zone in there to prevent a lot of those types of burns.

It seemed only natural that putting a little extra material underneath there would save the firefighters that problem and that ability and that potential to be burned in those areas and those areas aren't really breathable because of the material anyway. So yeah, that seems sensible, but that new style of trim, every department needs to evaluate whether it's good for them or not durability reflectiveness, repairs, you have to evaluate everything.

And because we do address a lot of that, In the NFPA standard. What's good. And what works for one department may not be good work for another department. So my advice is just to evaluate it.

Bob Keys, Retired FDNY Battalion Chief: [00:34:14] Absolutely like every innovation that's out there. Each fire department needs to evaluate whether or not that innovation better protects its own firefighters.

Having data from an a wear trial is the best way to defend change and innovation. I've seen that time and time again, across all departments that I get the privilege to visit with in north America. So one of the other big changes in the last 20 years, Jim, and I know you're passionate about this is that the NFPA has mandated.

That bunker gear be cleaned at least twice a year. Plus after every exposure to smoke weed products of combustion and potential carcinogens bunker gear has to go through a cleaning and annually. We have to see a advanced inspection of that gear.

So talk about how important that is and how that came about and how that's really protecting firefighters. It's a great, mandatory change that will save firefighters lives.

Jim Reidy, Retired SAFD Lieutenant: [00:35:08] We have actually had some of that in the standard probably five years prior to this standard, but it was kind of a gray area in the language.

I mean, with what we know today about carcinogen contamination, how it absorbs. How it will transfer from the outside of your gear when you brush it up against anything, how it off gases, it would seem to just make sense.

I tell people, you go out and you play a basketball game and you get all sweated up. You don't just put that stuff to dry and put it on the next day or the next hour, you take it off and you clean it. You go to work, you come home, you take your clothes off, you put them in the laundry. Why is it any different for us? Especially in those environments that we get into, why would we not clean that gear? And it's not only important for the firefighters, but it's also important for the citizens. We wear that gear everywhere. You know, you wear those pants, you know, how many EMS runs have you just thrown your pants on in the middle of the night and got up and made, made calls on it. You're contaminating everything that you come in contact with.

That to me was simple. The problem was, is justifying it and the financial expense that it's going to cost, but when you offset what it costs to clean gear, after every fire versus what it costs for one cancer case, that goes to the full limit all the way through that's a wash easily, and it's better for us.

And it's better for the citizens going into schools with that dirty gear. I mean, can you imagine over the years before we started really cleaning this gear? All the contamination. We were dragging all across our municipalities, into our schools, into our nursing homes in our hospitals. It just blows my mind.

And the pushback, I get it, financially. It's difficult, but I used to tell guys would clean those fire trucks more than we cleaned it. And there's something wrong with that.

So, I mean, that to me was a no brainer and we had significant discussions on that NFPA committee about that, like ours, but ultimately it's, what's best for us. It's what's best for our families and it's, what's best for the citizens. So you're protecting your investment and your not spreading those carcinogens all over the place.

Bob Keys, Retired FDNY Battalion Chief: [00:37:27] I'm sure that, um, yeah. Uh, across north America. I appreciate the fact that the NPFA 1851 committee put that into the standard.

So as we said before, it forces the fire chief, forces the municipality to have no choice, but to come up with a procedure to decontaminate year after every exposure.

Uh, I see more and more. Departments installing extractors in most of their stations, if not all of their stations so firefighters can easily decontaminate the gear.

I see more and more departments following Vancouver's lead from five years ago where their quartermaster responses with spare gear to the scene of every alarm where firefighters had exposed. And you guys in San Antonio have a great program now where your Quartermaster response to alarms, where firefighters are likely to have contaminated gear so it doesn't even have a chance to get back to the station and overlooked about need for cleaning.

Those innovations would not have happened had not NFPA changed the rules and forced departments to have to come up with a procedure to decontaminate gear after every exposure.

Jim Reidy, Retired SAFD Lieutenant: [00:38:36] Just in Texas, because that's long. No fire department or municipality has gone bankrupt because they have to clean gear after every fire.

Bob Keys, Retired FDNY Battalion Chief: [00:38:44] This also has, has, um, spun off a greater desire for fire departments too issue alternative PPE. There's no reason in the world I can imagine why we need to put on thermally protective three layer, bunker gear to go to a assist a civilian who fell out of bed or to go to a routine cardiac arrest.

And there's just no reason to wear that other than the fact that firefighters don't want to contaminate their station wear so they cover themselves up in their bunker gear. I've seen that for many, many years in FDNY but innovative departments across the country have now started issuing one and two layer PPE that does not include a thermal barrier because there is no need for that.

Uh, by issuing this alternative PPE, certainly on all of those EMS calls and any non-fire call. For example, elevator emergencies, power failures, assist civilians in various needs. They wear this single layer. FR material garment that looks just like bunker gear, most departments designed it a little bit different, so it's not to be confused. So firefighters won't enter a structural fire wearing a single layer garment, but this alternative PPE extends the life of the very expensive three layer bunker gear, and also reduces the exposure or the influence of exhaustion on firefighters by reducing that thermal retention of your own body heat. So we're reducing that stress that we talked about earlier is the silent killer of firefighters. ;This heat exhaustion. By going to the 90% of the calls, firefighters respond to, there is no fire exposure, danger at all, but when we only are issued one set of PPE, we wear that to most of the calls we go on.

So this alternative PPE has, has been a great innovation in reducing heat exhaustion problems, extending the life of the gear and reducing that exposure to our civilians, to gear that potentially carcinogens in its fibers.

So I know you've been involved in this conversation quite a bit, Jim and I, I know you've seen departments that are switching now to give them firefighters an alternative instead of wearing their structured gear on routine calls, do you want to please share your feelings about this type of technology? I appreciate it.

Jim Reidy, Retired SAFD Lieutenant: [00:41:07] If you had that kind of budget, I think it's great, but I, it makes me worry sometimes that the department will get one set of gear and then they'll get this other non firefighting gear if you make a fire car fire, dumpster fire structure, fire, you have to clean it right away afterwards.

If that's one set of gear that you have for that firefighters out of service, what happens? I mean, in my busier parts of town here, we do have two, three fires a day sometimes. It gets, it gets of kind of crazy.

So I think it's a great idea. I'd love it. Right after you cleaned your gear after every fire, and then hopefully get two sets of gear for your guys. Because my biggest fear is what's gonna happen is, is you'll get one set of gear and then you'll have that second fire.

And then that guy's going to be forced to wear that non firefighting FR outside. He's going to wear it into a structure and someone's gonna get hurt. You have to have those, those policies and guidelines and SOPs.

Firefighters in their nature, the kind of people that stand outside. So if that's all he has to wear, that's, that's what they're going to wear.

So I think it's a great idea to have that non-structural set, but I think the better idea is to make sure that we have two sets for everybody. You always have a clean set of gear on no matter where you are.

Bob Keys, Retired FDNY Battalion Chief: [00:42:30] I agree with you totally in a perfect world. Uh, firefighters should have two sets of structural firefighting gear and an alternative PPE, one layer or two layer for those non-fire calls.

As an alternative. What I have seen as, as being adopted like you have in San Antonio, if you have that quartermaster that responds to structure fires, a firefighter won't be put in that situation where he does not because his gear is contaminated. He doesn't have a second set of gear, many departments. A cache of spare gear that they delivered to the scene of fires to be able to justify the existence of an alternative PP that can't afford two sets plus a one layer garment.

They give out one set and they have a big cache of generic size gear that they deliver to the scene. So firefighters are never left without a three layer structural ensemble, of course, in the perfect world, two sets of structural gear and a single layer. Uh, PPE would be best, but I think we are moving in that direction that every month I see more and more departments coming up with a responding vehicle with a cache of spare gear.

Austin, Texas is doing that Fort worth is looking to start that up. As I just said before, Vancouver has been doing that for over five years. So let's talk about some other innovations in buggy in the last 20 years, since 9/11.

Um, some of the simple. Uh, that I remember seeing a change in his gloves have become way more dexterous. I remember the gloves I was wearing on 9/11. They had no dexterity at all. You had to take your glove off to change the volume on your radio.

To, to change channels on your radio. You had to take your glove off to do any kind of fine hand work, trying to force through the lock of a door you were forcing, working in an elevator environment, any type of fine finger work. You had to take your gloves off for, but now we're seeing, uh, not only better materials and more dexterous gloves, but also this evolution of cadet sizes.

I think everybody realized firefighters had different head shapes. And so our helmets were designed to have adjustments in them. But what people didn't realize is there's so many different hand sizes.

Some guys have great big hands, but shorter fingers. Some people have smaller hands, but really long fingers. And so NFPA came out with a sizing criteria that also included what we call cadet size gloves.

So can you speak to that, Jim? Cause I know you were part of that conversation has that evolved?

Jim Reidy, Retired SAFD Lieutenant: [00:44:55] Yeah. And so what people have to remember is just in general, that NFPI standards are minimum standards. So you have to meet minimum standards, but you can always go above that.

The, uh, the kid that size and came in alongside being the military sizing. When we changed from industry standard sizing on gloves to kind of what the military was using. That was the templates for it.

And then that sizing came in and, and you're right. Hands and feet are super personal parts of your body items. And it's almost different for everybody. And then, especially now, because we have so many more females on the job, their hands are different and that's just a biological reality of life.

Is that they have a lot of, uh, um, different sizing and different measurements also. So those cadet sizes help us really get to the a wide range. And we got some gigantic people on the job that have hands. I don't even know where they, I don't even know where they get gloves for, but, and then we also have the people that unfortunately are missing a half a finger or maybe a finger or whatever. So we have to make gloves for them too.

But I think that sizing has really shot us forward as a profession and really helped us make sure that we get gloves.

The 3d gloves are a real innovation now, too in sizing and dexterity. I mean, but we always say right that it's not a pair of isotoners and it's not meant to be, but it does need to be functional, but it's primary job is to protect you from the fire and anything, well that we do after that is good for the firefighter and good for the operation.

Bob Keys, Retired FDNY Battalion Chief: [00:46:35] Yeah. I agree. Can you speak to the other innovation by requiring a thumb loop on the wristlet of the jacket on our bunker gear, we've allowed departments to issue gauntlet style gloves that don't have a wristlet built into the glove.

And for me, personal experience wise, it's very hard putting a glove with a wristlet on, especially after it's wet or after you've taken it off to do some of those fine tuning kind of things. As I said, putting a glove with a wristlet back on for me was a big challenge. And now that we have this thumb loop built into the coat... the thumb loop ensures that your wrist is protected. If you don't have a wristlet on your glove, it makes sure that that's leaves stays down, protects all the way up to the beginning of your hand. And so you can wear a gauntlet style glove or gloves without a wristlet on it, which I found much easier to get on and off.

So can you share with our listeners about how that innovation happened. And, and who was instrumental in getting that into the standard?

Jim Reidy, Retired SAFD Lieutenant: [00:47:35] I think that was just, that was firefighter driven. There was one particular company that started producing that thumb loop. And I was like, why haven't we been doing this all along?

I think that that innovation is excellent. And now you get a sleeve with a thumb loop through it, or you just get the basic thumb loop by itself. But yeah, as far as the protection factor, I think it, it keeps the code in the interface operating the way it was intended to. And yes, I'm of the same opinion.

Gauntlets are a lot easier to use. You just have to make sure. By those types of gloves that interfaces with your coat correctly. I see people that pick up a glove and it's awesome and they put it on it's awesome, but they don't, they don't try it with their coat, but to make sure that it interfaces with the COVID opening properly, for lack of a better term.

But yeah, that fumble up is it's tremendous. I love it. We don't spec anything here without having some kind of numbers.

Bob Keys, Retired FDNY Battalion Chief: [00:48:33] So one other innovation that comes to mind since 9/11, of course, like so many innovations comes about after a tragedy. Um, so in, in January of 2005, after an overnight blizzard dumped feet of snow across New York City, a fire in a five-story non fireproof building in the Bronx flashed over in a wind-driven situation, trapping ladder 27 and rescue 3 members on the top floor of this building. They were forced to jump out a window on the fifth story.

Six firefighters jumped and, uh, two of them died that day. And the two that survived did share a rope that one had in his pocket. And, uh, That forced R & D and training at FDNY to develop the personal safety system, a repelling device that would allow firefighters that were trapped above the fire and had no other way out to lower themselves below the fire.

That innovation took a lot of work and dedication. As we mentioned before, Pat Woods was innovative and leading that cause and coming up with an amazing design, that's been adopted by departments all across the country. I know the personal safety system is, is controversial and some departments don't believe it's necessary.

Some states have made it mandatory for cities above a certain threshold to have to make sure that firefighters are equipped with that lifesaving device.

What's your opinion. And how were you in. On the committee, uh, when the PSS system was adopted and I think it was in 2006 or later?

Jim Reidy, Retired SAFD Lieutenant: [00:50:13] My opinion is I think it's a good idea.

We can't get it done here, but I think it's a good idea. And I think departments that don't want to issue with department wide, at least in your high story areas like here, we only have a couple of areas that have really have high rises. If you're not going to issue them for every person, then issue them every position at least to get us started.

So that at least those positions are on the trucks, in those high hazard areas or those high rise areas. At least each position we'll have it on the SCBA somewhere. And that way, at least those people that are responding to those types of structures will at least have at least the first and second in once second due

unfortunately. I don't think a lot of places realize that they need it, or it doesn't rise to the top of needs until they have a tragedy.

Bob Keys, Retired FDNY Battalion Chief: [00:51:05] Yeah. Which is unfortunate. Um, we would love to say that fire departments are proactive, um, in my experience were more reactive and it, it takes the loss of life or some serious, serious incident where people are severely injured or potentially severely injured to get the attention and, and justify the expense of better protecting firefighters, which is a shame, but we are making inroads into that and thanks to the efforts of, of you and people like you that serve on these committees that push forward initiatives and set standards to make firefighting a little better.

Jim Reidy, Retired SAFD Lieutenant: [00:51:40] Yeah. Pat was instrumental in that him and Danny both drove that really well. So.

Bob Keys, Retired FDNY Battalion Chief: [00:51:45] That's just about it for my list of innovations and changes for better protecting firefighters since September 11th, 2001 remembering that date and that time in our lives, we will never forget.

In summation. Jim, is there anything else that you would like to add that you've seen that has improved firefighters safety through design through standards or just through a need?

Jim Reidy, Retired SAFD Lieutenant: [00:52:13] When I was thinking about this podcast and what we were going to talk about, I, I just remembered one really insane thing we used to do.

My early days, when I came on the job, if a, if a helmet got damaged, you sent it down to the maintenance shops and they repaired it and they sent it back to you and it had divots on it and they got banged up those old federal helmets we used to have.

And then I, I remember one day the guy said I was down there and I saw him using a spray can, a lacquer paint to paint the helmets. After we stopped laughing and then they said, yeah, they were using car Bondo to fix the divets and then one of my very industrious firefighters took, uh, a lighter and put it on the helmet and let it sit there for a little bit. It was on. And then all of a sudden it flamed on.

The spray paint lacquer, I guess, on the helmet, flamed up. We're just like amazed and thought. That's insane.

After that, I was on the safety committee at the time and we, uh, politely informed the administration that that practice could not happen anymore. So then we, we actually started looking at new helmets that were a little more durable and went through an evaluation and ended up picking out a new helmet.

But I just, I laugh when I think about spray paint and the helmets, the repair. And I wanted to note that people talk about the NFPA committees and, and the, the perception I think is that the manufacturers run those committees and we're just, all the firefighters are just all along for the ride. Um, I represent, I don't represent San Antonio. I represent the Texas state association of firefighters on there. FDNY has a person on there, but there's 35 people on the committee. And I would tell you that the percentage majority are firefighters or retired firefighters or people that are still on the job, but the majority of the people on there are firefighters and fire chiefs.

Um, but yeah, the manufacturers don't run that committee that the firefighters have great influence on that committee. And when something doesn't sit well with the firefighters on that committee, we get up and we talk about it and we make sure that everybody's on the same page when we vote on things.

That's all I have to say. I appreciate the opportunity. Bob, it's always nice to chit chat with you.

Bob Keys, Retired FDNY Battalion Chief: [00:54:34] Well, thanks, Jim. Um, I'm sure everyone who listens to this podcast will lean something from your innovation, from your personal perspective, for your dedication and for your love of firefighters everywhere even the ones that you don't know.

Your work is making a difference in making firefighting safer, wish you all the best of luck as you continue. And the next chapter of your life.

Firefighting has been my whole life has, it has been yours. And to be able to continue to. Share best practices and lessons learned and understand innovation, um, has been a reward for me since I retired.

I, I hope you stay involved and continue to share your knowledge about how innovations happen and how to better protect firefighters because the firefighting community will be a better place. Um, as long as you're still stay involved. So

Thank you LT Jim Reidy from San Antonio

Let's never forget. And always remember our firefighters from September 11th, 2001, and those that are still continuing to fight illnesses and let's hope that our country still protects and maintains the health of those firefighters that have been exposed in our fighting deadly diseases. A safe month of September to our firefighters and a safe future. Take care and God bless. .